MicroFab: Microfabrication through Electrodeposition

This is a trip report of a visit I made in September 1998 to John

Madden at MIT to work on the microfabrication technique which he describes

in his patent

with Prof. Ian Hunter.

The goal of the two week stay was to duplicate the results described in

the patent, develop some improved control software for running the experiment

and try to improve the control of deposition, especially along horizontal

surfaces.

Update 7/1/99: The Information Sciences Institute at USC has independently

developed a rapid microfabrication technique also using electrodeposition.

See EFAB.

Experimental Setup

The general approach is to use a fine-tipped probe in an electroplating

solution to locally electrodeposit metals out of the solution to form microstructures.

We used 4.7 volts to deposit nickel out of a nickel sulfamate solution

onto a copper surface (or other parts of the previously-deposited nickel

structure).

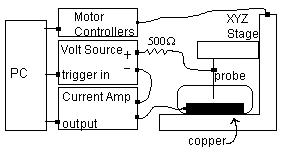

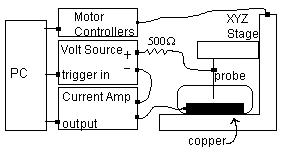

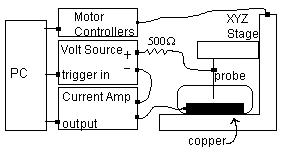

Below is a diagram of the setup we used, followed by details on each

of the components.

microfabrication setup

-

PC Computer: Windows 95 with a National Instruments PCI-MIO-16XE-10

I/O board ($1995). This is an internal PCI board which connects to an external

BNC-2080 breakout board ($340) with screw terminal connections. We use

one A/D input (-10V to 10V range) and an 8 bit digital output.

-

Motor Controllers: One Compumotor

LN Drive for each of the XYZ axes ($1680 each). Each controller is

set up for 100,000 steps per revolution. Each controller takes three digital

inputs: step pulse, counter-clockwise select, and standby. (One digital

output from the PC controls the standby for all three motors, so the total

digital outputs used is 2*3+1=7 .)

-

XYZ Stage: Three-axis stage from New

England Affiliated Technologies with one CompumotorLN57-51-MO

microstepping motor per axis ($127 each).

-

Voltage Source: HP 3245A universal

source ($5050). This is programmed to cycle through three different voltages

(0V, 1V, 4.7V) based on the trigger input from the PC. (The trigger uses

the eighth digital output from the PC.)

-

Current Amplifier: Keithley

428 ($3390). This has a voltage output, converting one milliamp in

to one volt out. Its range is -10mA to 10mA (-10V to 10V output, which

also corresponds to the A/D range).

-

500 Ohm Resistor: The maximum voltage is 4.7V. The current amplifier

has a limit of 10mA, so a 500 ohm current-limiting resistor limits the

current to 9.4 mA.

-

Probe: 35/25/Epoxy Insulated 30M, catalog #30-10-119721D from FHC,

Brunswick, ME, 207/666-8190. ($87 for 3 probes.) The probe is epoxy insulated

up to the tip. Epoxy worked better than glass which seemed to chip quite

easily slowly exposing more of the tip. The epoxy would fray at the tip

a little bit, but did not seem to slowly keep retreating through use like

the glass.

-

Copper: We actually used the connector sawed off from an ISA board.

It was easy to solder a wire to the connector lead off one of the connector

contacts. The solder joint is covered with protective tape before putting

it in the nickel sulfamate. The copper is inside a dish which can be filled

with the nickel sulfamate. Actually, since the work area is quite small,

we found that it is enough just do use a syringe to deposit a large droplet

onto the copper surface surrounding the probe. It forms a meniscus and

clings to the probe. Therefore we didn't have to fill and empty the dish

every time.

A note on pricing

The prices included above are for the setup we used, but some of the equipment

is clearly overkill. For example, a fully-featured HP 3245A universal source

is certainly not necessary to output 1V and 4.7V. Instead, a buffered output

from the existing D/A board might work as a much less expensive alternative.

Likewise, instead of the Keithley 428 current amplifier, it might be possible

to monitor the voltage across the 500 ohm resistor as a current sensor,

although we haven't tested this. A less expensive second-hand XYZ stage

may be available from ServoSystems.

Of course, a killer app of this fabrication technique would be to manufacture

an adequate stage for the process itself.

Procedure

I will describe the procedure by describing the software which implements

the depositing algorithms. John Madden's lab was already set up to use

Symantec's

Visual Cafe Java development environment, so I continued with its use

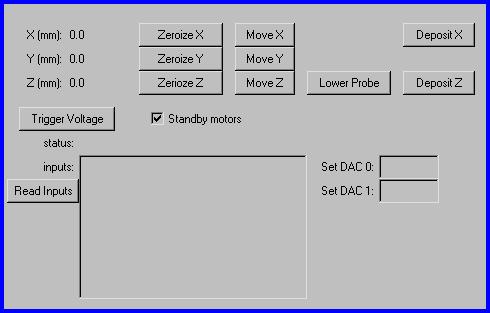

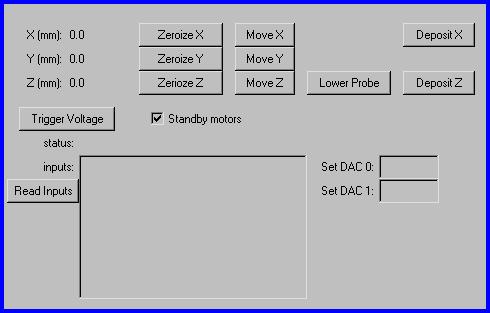

to write the control software which is an applet called MicroFab. Below

is a screen shot. Included is a zip file with

all the code, except that the file RealTime.java links to native code in

rtlib.cpp and other files supplied by the I/O board manufacturer which

I could not include.

MicroFab main screen

In the upper-left of the screen are readouts of the present position

of the probe on the XYZ stage. Next to the readouts are buttons to zeroize

these readouts to give a new origin for any of the axes. The MoveX, Move

Y and MoveZ buttons simply position the probe without any feedback. (After

you press the button, MicroFab shows a dialog box where you specify how

far to move the probe.) The Trigger Voltage button simply sends a pulse

to the volage source to trigger it to its next value as it cycles through

0V, 1V and 4.7V. And the Standby Motors checkbox turns on and off standby

for all three motors. (In standby, the motors are not powered and the shafts

can be manually turned. With standby off, the motors are activated and

shafts locked.) Set DAC 0 and Set DAC 1 are for testing the D/A outputs

(not used in the present setup) and the Read Inputs button displays the

values of all A/D converters in the "inputs" box.

The real action is in the three buttons on the upper right as described

below.

Lower Probe

To lower the probe, the MicroFab software sets the probe voltage to 1V.

Repeatedly it lowers the probe in the Z direction by one motor step and

reads the probe current. (One motor step results in 0.02 microns probe

movement.) One volt is below the threshold for depositing, so it is only

a test voltage. If the current jumps above a threshold (0.01 milliamps)

then the probe has contacted the surface and MicroFab stops lowering and

sets the voltage back to zero. One detail: while preparing to lower, after

setting the voltage to 1V, MicroFab waits one second before lowering because

there may be some initial capacitive current as the probe charges up.

Deposit Z

Depositing a vertical column in the Z direction is the first operation

we tried, and it worked well on the first attempt. I found it easy to get

repeated results. To deposit in the Z direction, the MicroFab software

sets the probe voltage to 4.7 volts. It repeatedly reads the probe current.

When the probe current is above a threshold of 2.5 milliamps, this means

the probe is close to the growing column of nickel and moves the probe

up one motor step (0.02 microns). If the probe current is below the threshold,

MicroFab maintains the probe position while the nickel column is presumably

growing up to meet the probe. If MicroFab waits for one minute without

reaching the current threshold, it quits. Under normal circumstances it

never reaches this timeout, but when experimenting with different deposit

rates by setting different voltages or current thresholds, it may time

out. This process continues until a column of desired height is deposited.

With the caveat that I could not get an SEM micrograph, just looking through

an optical microscope, I estimate that with the probe specified above the

column is about 20 microns wide. (With a more finely-tipped probe, this

would be thinner.)

Due to the hardware, the speed of depositing is limited to how fast

it can read the I/O board to sample the probe current. Empirically, I measured

one A/D read per 0.3 milliseconds, which includes communication with the

I/O board. At 0.02 microns per motor step, this is a maximum of 66 microns

per second. A normal rate for nickel depositing process is around 10 microns

per second, so the control software is faster than the process, though

not by much. If this becomes a problem (which it was not for us), then

MicroFab can step the motor by a few steps between reading the A/D without

affecting the smoothness of the deposit. Alternatively, we can use a faster

A/D.

Deposit X

Before describing the algorithms we tried for depositing in the X direction

along a surface, which met with some difficulty, I should point out that

we did have success in depositing horizontally "up in the air" as long

as the probe was not in danger of hitting a surface. For example, I made

an inverted L by depositing a column vertically, and then using the same

algorithm as Deposit Z, but moving the probe horizontally off the tip of

the column. Likewise, I deposited a vertical column, and then moved the

probe horizontally in the X and Y directions to draw out the letter Z.

These are simple uses of the same algorithm as Deposit Z.

However, there is a difficulty in depositing along a surface because

the probe can get caught. When MicroFab uses the "Deposit Z" algorithm,

it sets the voltage to 4.7 volts and checks the current. If the current

is above the threshold, then it moves the probe by one step. (In this case

it would be in the X direction along the surface.) But if the probe is

caught on a bump on the surface, it will be contacting and the current

will certainly be above the threshold. So MicroFab will mistakenly step

the motor. As the probe remains caught, MicroFab will step the motor quickly

until it thinks the desired amount has been deposited, but none really

has.

To get around this, we first tried holding the probe several tip diameters

above the surface at 4.7 volts and just scanning back and forth. But there

is a problem of positive feedback here. If a bump on the surface is slightly

higher, the electric field will be stronger and more metal will be deposited

here. That makes it higher and the electric field even stronger compared

to the rest, causing it to grow even more on the next scan. When I looked

at the result, instead of an even deposit underneath the scanning area,

there was one poorly-formed column that reached up to the height of the

scanning probe tip.

A different way to address the problem of the probe getting caught while

depositing along a surface is to make the probe "hop." This is presently

implemented by the MicroFab Deposix X button as follows. MicroFab lowers

the probe to the surface then deposits a column to a height of 0.1 microns

using the Deposit Z algorithm. Then it turns off the voltage, lifts the

probe 25 microns and moves it horizontally 25 microns. The process is repeated,

lowering the probe to the surface, depositing to a height of 0.1 microns

and hopping 25 microns. Once the first layer of the desired horizontal

length is complete (such as 250 microns), MicroFab moves back to the original

location and repeats the process, this time depositing vertically each

time to a height of 0.2 microns above the surface. This is repeated layer

by layer up to the desired total height.

The results were not as expected. Looking in the optical microscope,

instead of a continuous wall, I typically saw a row of columns spaced 50

microns apart, with each column of the desired total height. A likely explanation

is that MicroFab properly deposits the first column up to the height of

0.1 microns, lifts the probe 25 microns and moves horizontally 25 microns.

But when it goes to lower the probe to the surface, the probe encounters

an electrical contact before it fully reaches the surface, due to some

stray material hanging off the previous column, or because the probe may

be too fat. Since after "lowering", the probe is above 0.1 microns and

in electrical contact, MicroFab does not do any vertical deposit, but raises

the probe 25 microns and moves horizontally again 25 microns. This time

MicroFab successfully lowers the probe to the surface, now 50 microns away

from the original column. Thus it skips every other 25 micron site.

Future Work

Although we could not get reliable results with the Deposit X algorithm,

I should mention that during one trial I did see a fairly continuous wall

as expected. So this suggests that under the right circumstances the procedure

can work. But I could not repeat this result. For future experiments, I

would like to try the following:

-

In the Deposit X algorithm, after lowering the probe to the supposed surface

and getting electrical contact, as long as the probe is near the proper

height, MicroFab should apply the voltage for a period anyway, even though

it will be above the current threshold. This may prevent it from skipping

every other column and "fill in" the wall more.

-

The probe we used may have simply been too fat. A sharper probe may allow

the algorithm to work better.

-

For horizontal depositing, try angling the probe 45 degrees and using an

algorithm more like the original Deposit Z. In other words, first lower

the probe to the surface, then raise about one tip diameter. Then begin

depositing, moving a step horizontally when probe current is over the threshold.

Since the probe is angled away from the direction of motion, perphaps it

will not get caught on bumps on the surface. Of course, using an angled

probe only allows horizontal depositing in one direction, but with a proper

"raster scan" regime, this may be useful.

-

I did not get an SEM micrograph of the vertical columns, but I suspect

they are not as smooth as we would like. There are a few possibilities

to try: change to a voltage somewhat lower than 4.7 volts, which will yield

a slower but maybe smoother deposit.

-

Also, try a lower current threshold: It may be possible to use a much more

sensitive reading than 2.5 milliamps so that the probe can be moved before

the deposited material fully reaches the probe. The present technique may

be causing the probe wait too long and then move in bursts, resulting in

a less smooth surface.

-

It may be possible to estimate the depositing rate and keep the probe moving

slightly ahead of the growing column, even while the probe current is under

threshold. Again this may smooth out the depositing process.

-

And lastly, there are several other materials besides nickel which can

be deposited, such as other metals, semiconductors and polymers. Most notably,

there may a polymer which conducts during the electrodeposition, but which

can be later immersed in a dopant which would change it to an insulator.

Therefore by alternating between depositing this polymer and nickel, and

later doping the polymer into an insulator, it may be possible to create

structures with electrically isolated regions.

Conclusions

Microfabrication using electrodeposition is an inexpensive process using

simple equipment, low power levels and relatively benign materials such

as nickel sulfamate. I found the process very forgiving, considering that

we were controlling if from a Java application running within Windows 95

(as opposed to dedicated control hardware). Depositing material vertically

and in circumstances where the probe cannot get caught yields repeatable

results. More work needs to be done on depositing material along a surface

where the probe can contact pre-existing material.

Back to Main Page